Maintenance of gates and curtains

We produce service:

- sliding, sectional, roll and swing gates;

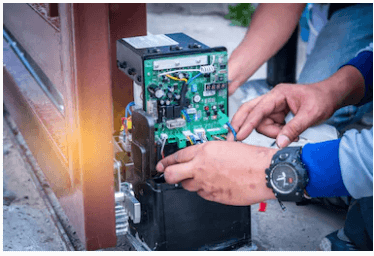

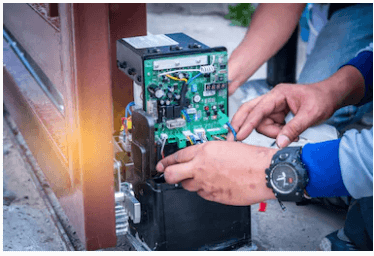

- gate control units and electric drives;

- automatic roller gates (roller shutters).

Modern roller gates installed in the entrance areas of industrial enterprises, office centers, etc. are quite complex and high-tech devices. For their smooth functioning, regular maintenance is required to help identify defects and eliminate them promptly.

Regulations for the maintenance of fire CURTAINS MBA

- General diagnostics of curtains, test lowering and lifting (in manual mode and in the fire protection system operation mode);

- Assessment of the overall condition of the curtain, checking for corrosion and contamination;

- Checking the condition of the curtain cloth (the condition of seams, side pockets, the presence of breaks, etc.);

- Checking the operation of the guides (the presence of gaps, the condition of the guides), cleaning from large debris;

- Checking the condition of the winding of the web (the presence of distortions, folds, etc.);

- Checking the operation of the shut-off tire (the quality of the clamp, the level in the niche of the housing, the density of the fit to the floor surface);

- Checking the attachment of the web to the shaft;

- Checking the condition of fasteners (consoles, side covers, side tires);

- Checking the operation of the drive, motor mounting, the condition of the fuses;

- Diagnostics of cable supply from the motor;

- General system operation check;

- Checking the final position of the curtain cloth, adjusting the limit switches;

- Checking the mains voltage;

- Checking the battery charging voltage (26.5 - 27.5 V at 220 C);

- Voltage monitoring (power supply malfunction signal);

- Disconnecting the network (electrical equipment must be in working condition from the battery);

- Lifting and lowering of the curtain cloth (by the button on the control unit or remote switch);

- Control of the space on the way and in the place of lowering the canvas;

- Significant comments on the PPB.

Regulations for the maintenance of fire GATES MBA

- External inspection, inspection of the gate operability, assessment of compliance with the rules and safety of operation, verification of the reliability of fastening of the main components;

- Defects of the web (no deformation, damage, contamination, increased wear, symmetry of winding on the shaft (if any), no problems of winding on the shaft (if any), breaks and damage to the web of fire pockets), guide rails (no deformation, damage, strong fastening, no damage to welds), consoles (no deformation, damage, strong fastening, no damage to welds), shaft (horizontal installation, no damage), shaft axes (fully located in the bearing), bearings (all mounting parts are in place, the tightening torque meets the requirements), electric drive (no unusual noise during operation, oil leaks, tightening torque meets the requirements, all mounting parts are in place), automation (the control unit housing is not damaged, the keys work, the plug is easily pulled out);

- Condition check, broaching of all threaded connections, adjusting screws;

- Checking and adjusting the limit switches of the electric drive;

- Checking the operability and adjustment of the emergency manual lifting gear of the electric motor;

- Checking the condition and reliability of fastening of side locks of lamellas, wind hooks;

- Checking the symmetry of the winding of the web on the shaft, checking and the presence of distortions, jamming, troubleshooting;

- Troubleshooting minor problems;

- Checking the automatic lowering of the gate from the APS system;

- Significant comments on the PPB.

Regulations for the maintenance of INDUSTRIAL TYPE ROLLER GATES MVA

- External inspection;

- Health check;

- Assessment of compliance with the rules of operation and safety of operation;

- Checking the reliability of the fastening of the main nodes;

- Checking the web: no deformation, no damage, no contamination, no increased wear, symmetrical movement of the web;

- Checking the guide rails (if available): no deformation, no damage, strong fastening, no damage;

- Checking consoles (if available): no deformation, no damage, strong fastening, no damage to welds;

- Shaft inspection (if available): horizontal installation, no damage, bearing diagnostics (all mounting parts are in place, the tightening torque meets the requirements) Checking the electric drive (if available): the absence of unusual noise during operation, oil leaks, the tightening torque meets the requirements, all mounting parts are in place, if necessary, adjustment of limit switches;

- Automation check (if available): the body of the control unit is not damaged, the keys work, the CEE plug is easily pulled out;

- Broaching of all threaded connections, adjusting screws;

- Checking the operability and adjustment of the emergency manual lifting gear of the electric motor;

- Checking the condition and reliability of fastening of side locks of lamellas, wind hooks (if available);

- Troubleshooting minor problems.

| Make an application on the website, we will contact you soon and answer all your questions. | Order service |