Rolled industrial gates AL-120 insulated

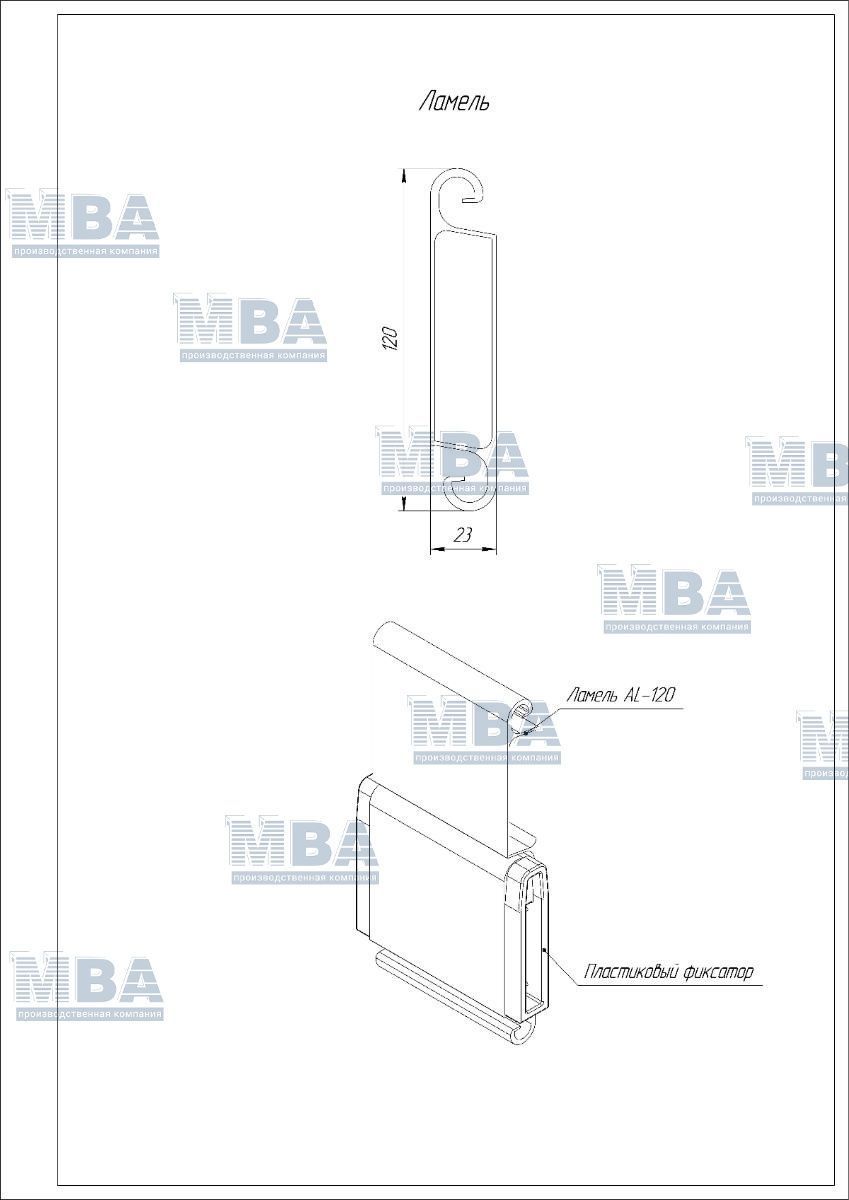

Insulated roller gates AL-120 (AL120) of the MBA production company are installed in industrial premises, aircraft hangars, warehouses, sorting units and other industrial premises. This type of gate solves the problem of overlapping large openings - a width of more than 5 meters. The canvas consists of durable aluminum lamellas with a thickness of 23 mm with a filling of solid polyurethane foam, which provides thermal insulation properties of the structure. The AL-120 roll gates with reinforced extruded profile are designed for installation in areas with high wind loads. A special design of the AL120 profile in several canvases using sliding trusses allows you to protect openings for aircraft and special equipment up to 40 meters wide. One canvas can be used to make industrial insulated gates up to 12 meters wide.

₽16,000/м2

Order

Completed works

Automatic Roll gates 19x4.5 m for Airfield hangar

Automatic Roll gates 19x4.5 m for Airfield hangar  Automatic roll-up gates for aircraft hangar

Automatic roll-up gates for aircraft hangar  Large roll-up gates for the company's warehouse

Large roll-up gates for the company's warehouse Описание

Advantages of rolled industrial gates MBA made of aluminum profile AL-120

MBA is the only manufacturer of large-sized aluminum insulated gates in Russia - an analogue of the foreign manufacturer Hormann (Hormann, Hermann, profile HR116). The AL-120 profile is well known in the territory of the Russian Federation. Gate products made of aluminum profile are filled with polyurethane foam and in terms of price/ quality are superior to their European counterparts. Industrial gates are manufactured in Kolomna, Moscow region, at an enterprise with modern high-tech equipment.The aluminum profile is light and not subject to corrosion, the margin of safety of gates made of such material is impressive, the wall thickness of 1-2 mm allows you to produce structures with a width of 12 meters with one canvas, and when using sliding trusses, allows you to install our products on openings with a width of 40 meters.

Characteristics of production external roller gates

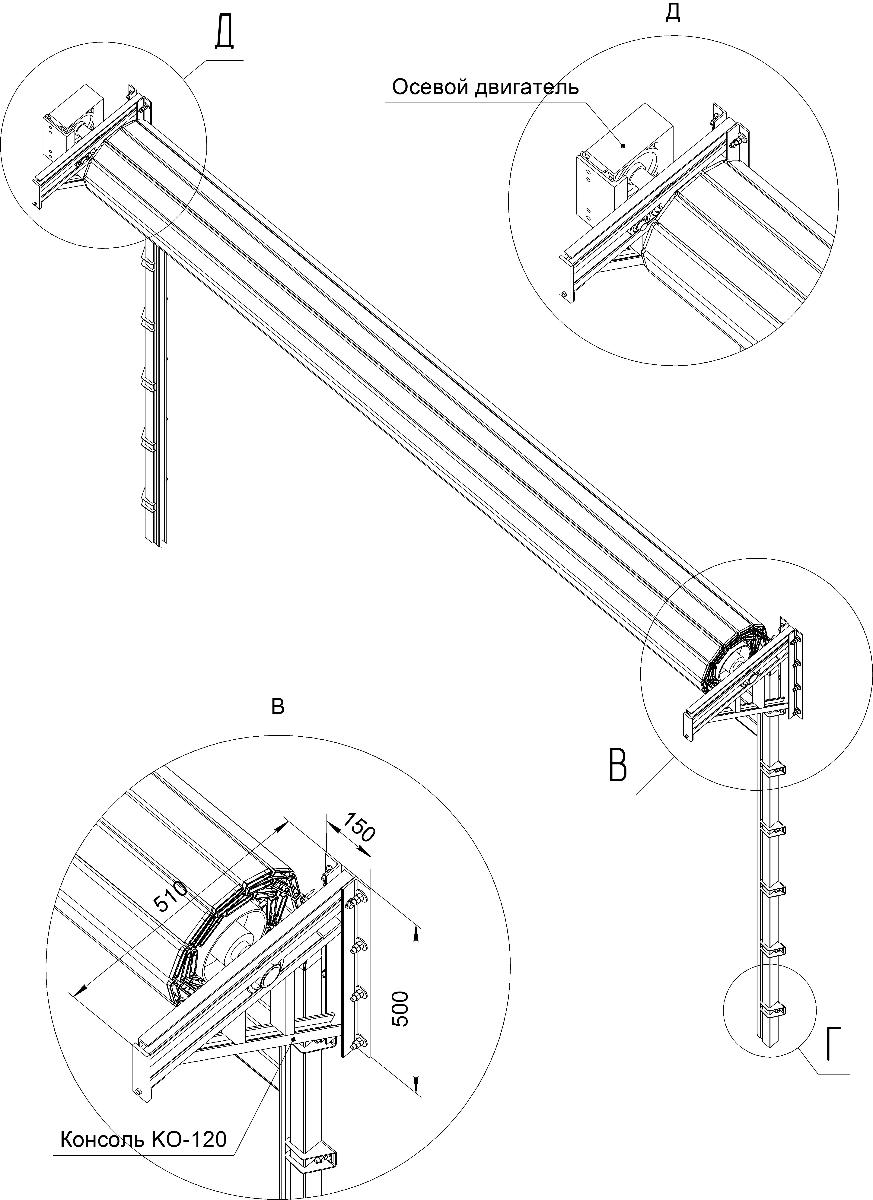

- The design uses sliding-type consoles, which reduces the load on the guides, and also allows the canvas to fit more tightly to the opening. Thus, the tightness increases, heat loss is reduced to a minimum, friction decreases when the web moves in the guides, and the resource increases.

- For regions with a high wind load (II, III, IV, V), the roller shutter is reinforced with lamellas made of extruded profile 1.5 mm thick. To prevent the web from leaving the guides, special wind hooks are used.

- The thermal conductivity corresponds to 36 centimeters of concrete wall.

- The speed of opening and closing the gate is up to 0.35 m/sec.

- The delivery of finished products is carried out practically assembled, which greatly facilitates installation, increases the speed of commissioning.

- Unlike other analogues, industrial roller gates made of the AL-120 profile are Russian-made products, which makes it possible to work effectively within the framework of the import substitution program. Also, in the warehouses of our production, components for all types of our products are always available, which allows you to repair or service in the shortest possible time. You will not need to expect components from suppliers.

- At the request of the Customer, the design can be equipped with additional equipment (photocells, optical contact strip, traffic lights).

Buying gates of the MBA trademark – you buy high-quality products and can be sure of their reliability.

| Material | Aluminum with double wall, with internal filling | standard |

| made of rigid PU foam, powder coated according to RAL | ||

| Maximum dimensions of the gate | Maximum width, mm (one canvas) | 11 500 |

| Maximum width, mm | 40 000+ | |

| Maximum height, mm | 15 000 | |

| Dimensions, weight of the profile | Wall thickness, mm | 1-1,5 |

| Lamella thickness, mm | 23 | |

| Lamella height, mm | 120 | |

| Covering surface, mm | 98 | |

| Weight per square meter of canvas, kg | 10,6 | |

| Mass of the linear meter of the profile, kg | 1,06 | |

| Consoles | OKD-6, OKD-8, KC-104, KO-120 | standard |

| KO-120У | optional | |

| Side profile plugs | metal retainer | standard |

| Electric drive | Axial motor | standard |

| Intravenous engine | standard | |

| Supply voltage: single-phase motor / three-phase motor 220V/ 380V | standard | |

| Temperature mode of operation of the electric motor and automation: | ||

| • axial with integrated control unit | from –5 before +50 °С standard | |

| • intravenous | from –20 before +50 °С standard | |

| • axial special | from –35 before +50 °С optional | |

| Dust and moisture protection of the electric motor | IP 54 standard | |

| IP 65 optional | ||

| Type of emergency lifting of the electric motor: | ||

| • handle (collar) | optional | |

| • chain reducer | standard |

Depending on your needs, we will be able to produce insulated roller gates according to individual sizes, check with the manager.

The gate structure is designed to work in the following conditions:

-

Number of cycles - no more than 100 lifting and lowering cycles per day

-

Air temperature: - 40⁰C to +50⁰C

Construction of street insulated industrial gates

Our production roller gates are significantly different from conventional roller shutters (roller gates), which are represented on the market by popular brands, industrial MBA gates are much stronger. The reinforced structure of the AL-120 is obtained due to a thicker lamella wall, a larger insulation layer, the use of powerful seals, European engines and strong welded structures. A special "floating" bearing unit UCFL208 is used as support bearings, which allows to prevent the shaft from jamming in case of natural design distortions.

Rolled warm production gates with a door

Many people believe that it is impossible to make a gate or a door in a roll gate due to the fact that the lamellae are narrow and overlap each other when winding. This is partly correct, but there is a solution that allows you to make a pass in a roll gate. To do this, you will need to narrow the opening a little, although it is possible that the size of the opening will practically not change. A special metal structure is made into which the door is built. This design can be stationary, or it can be folding. In this case, the width of the passage does not narrow.

Wind load on the canvas

Mba gates with AL-120 profile are successfully installed in regions with high wind load, up to the 5th wind region (Far East, Stavropol Territory). The wind pressure can withstand additional wind hooks installed in the canvas and retaining slats in the guides.

How to check the stability of the gate, roller shutter and roller shutter to hacking according to GOST

Usually, industrial roller gates are installed on the territory of factories and enterprises that are under protection and the issue of gate burglar resistance is not relevant for them. But sometimes roll-up gates are installed on unguarded detached buildings. For such premises, the issue of burglary resistance is relevant. Large industrial gates have considerable weight and it is quite problematic to lift them even with the help of a special tool.Tests according to GOST GOST R 52502-2012 p. 5.1.2.1, tab. 2. (National Standard of the Russian Federation. Metal roller blinds) implies testing of the gate design:

- to extrude the web under a certain load from the guide (pressure into the edge of the web);

- extrusion from two guides (pressure in the center of the web);

- pressing the web up;

- resisting hacking with a variety of tools.

Reinforced industrial gates of large dimensions

For rolled insulated gates of large size and for an area with a high wind load, it is possible to make reinforced gates. In addition to the wind hooks described above, lamellas made by extrusion are used. As a result of the manufacture of lamellae by extrusion (extrusion), aluminum is compacted and becomes more durable. The thickness of aluminum on the locks, with this method of production, is 2-3 mm, the design is also more durable due to the seamless manufacturing method.

VIDEOS (11)

VIDEOS (11)

BIM models

BIM models

Tech documents

Tech documents

technical specifications 79,6 кб

INSTALLATION INSTRUCTIONS 694,5 кб

WIRING DIAGRAM (KO-120) 175,5 кб

WIRING DIAGRAM (KO-120U) 173 кб

THE TASK OF PREPARING THE OBJECT 596,5 кб